Know-How & Company Assets

Italtecnica relies on a solid technical know-how based on the specific skills of its work teams combined with the vast experience gained in over 35 years of work as lead player in the automotive industry.

The professional effectiveness, derived from the combination of engineering knowledge and adaptability developed in the research for technical solutions, presents our work as an added value to solving a simple problem, providing the customer with a completely personalized approach tailored on their needs.

idea

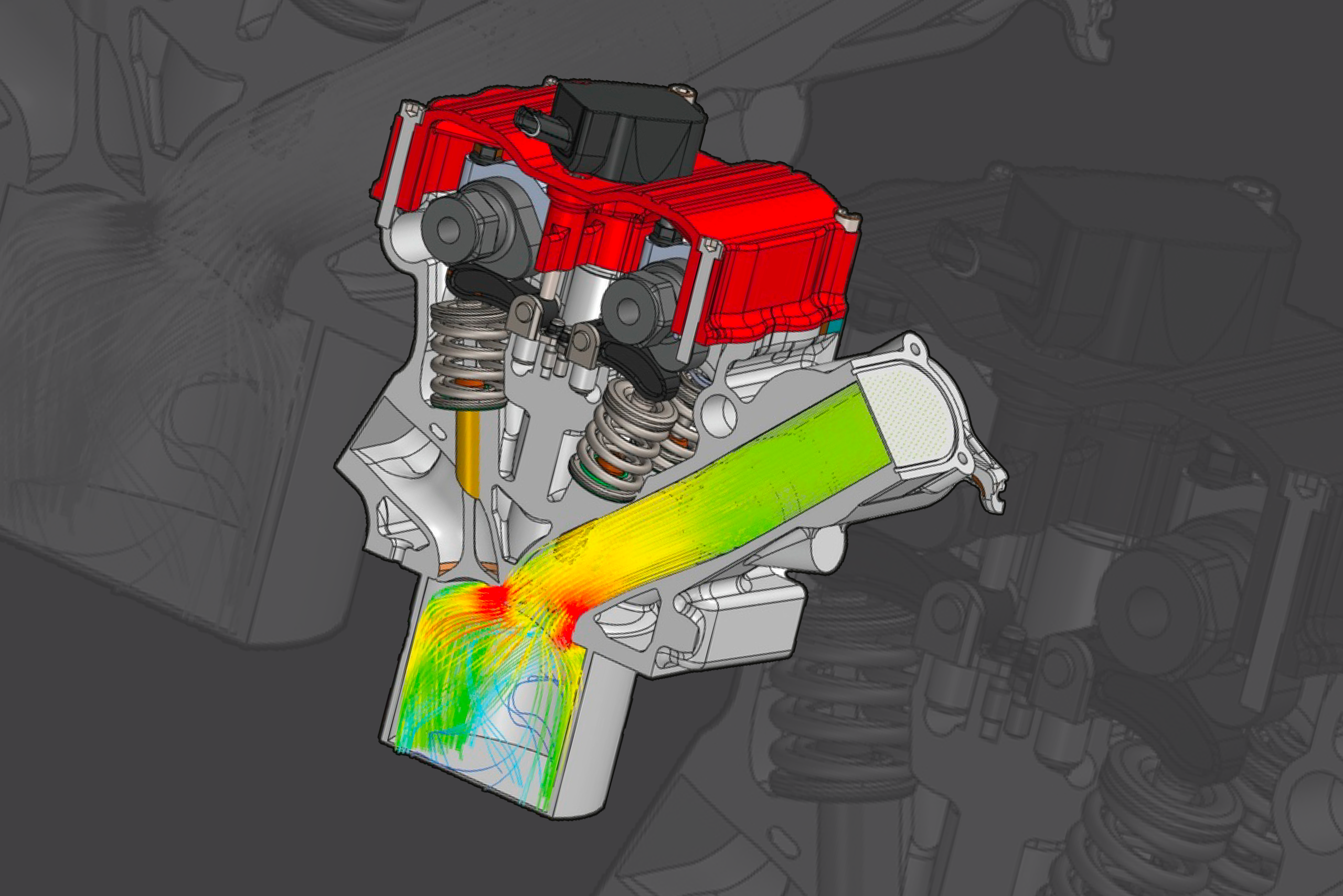

The internal Research & Development department is the mastermind behind the futuristic projects of Italtecnica which, with the numerous patents it holds, contributes in a fundamental way to concretize the demands of our customer base.

Special parts

One-off vehicles and prototypes are our specialty.

Our company structure is able to offer the design and production of special components for powertrains and custom-made chassis, using the most advanced technologies of CNC machining, laser cutting and metal 3D printing.

Our turn-key approach also includes, following the design and production phases, a wide range of tests by means of which we optimize and validate the components made so as to deliver a readyto- use product to the customer.

Engineering

The extensive experience gained in the design of high-performance powertrains for the racing world makes our engineering department the cornerstone in order to offer highly innovative and specific solutions for each type of vehicle. The latest technology in the CAD field supports our expertise in order to thoroughly analyze production and validation processes.

Vehicle Equipment

Our integrated approach to Powertrain and Chassis development provides, at the customer’s specific request, with a customized vehicle fit-up solution. The more than thirty years of experience in the management of the racing programs of the most famous car manufacturers in the world allows us to have a 360° view of the project we are taking care of, going not only to design and manufacture the key components of the vehicle, such as engine and chassis, but also implementing the auxiliary systems in the car, thus ensuring a high level of quality, efficiency and reliability of all systems. We also provide technical support in the construction and processing of special vehicles.

Testing

Our test rooms for endothermic engines and electric powertrains are equipped to perform Development, Validation and Duration Tests.

Our highly qualified staff is able to conduct tests with ISO9001 quality standards and customspecified according to the specific requirements of the customer.

Follow Up

Our structure equipped with cutting-edge technologies allows us to provide the customer with a follow-up service after taking care of its project, in order to assist it in the most congenial way during the process of using the components developed, produced and mounted on its vehicle.

Company assets

Powertrain

• 7 Automated Test Rooms for Internal Combustion Engines

• 1 Test Room for Electric Powertrains

• 1 Dyno Rolling Bench

• Flow Bench, Lubrication Bench and Camshaft Bench

• 12 Assembly and Teardown Stations

• Metrological Room

• CNC Component Construction Machinery

Chassis

• CAD Design Softwares and Finite Element Method (FEM) Structural Validation Softwares

• Chassis Construction with CMM Feedback Plan

• 2 TIG/MIG Soldering Stations

• CNC Component Construction Machinery

• Sheet Metal Processing with Laser Cutting Machine

Vehicle Equipment & Customization

• 4 Vehicle Lifting Platforms

• Wheel Alignment Bench

• Dedicated personnel with specific training for high-performance vehicle testing

Discover more about our projects!

*Only non-confidential projects are reported.