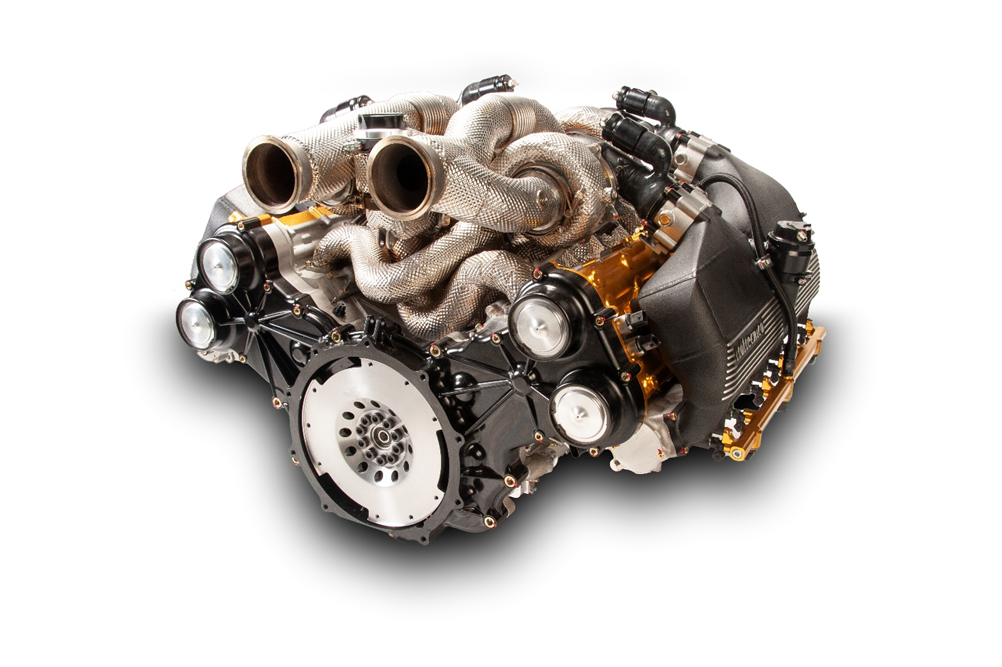

In an age where downsizing dominates, there is still room for large-displacement engines, such as the 7.0-liter, quad-turbo V12 installed on the Krafla by Giamaro, a small Italian hypercar builder based near Modena. The company was founded in 2021 by Giacomo and Pierfrancesco Commendatore (father and son). This is an ambitious project aiming to join the elite of hypercars. The goal is to make the first customer deliveries in 2027.

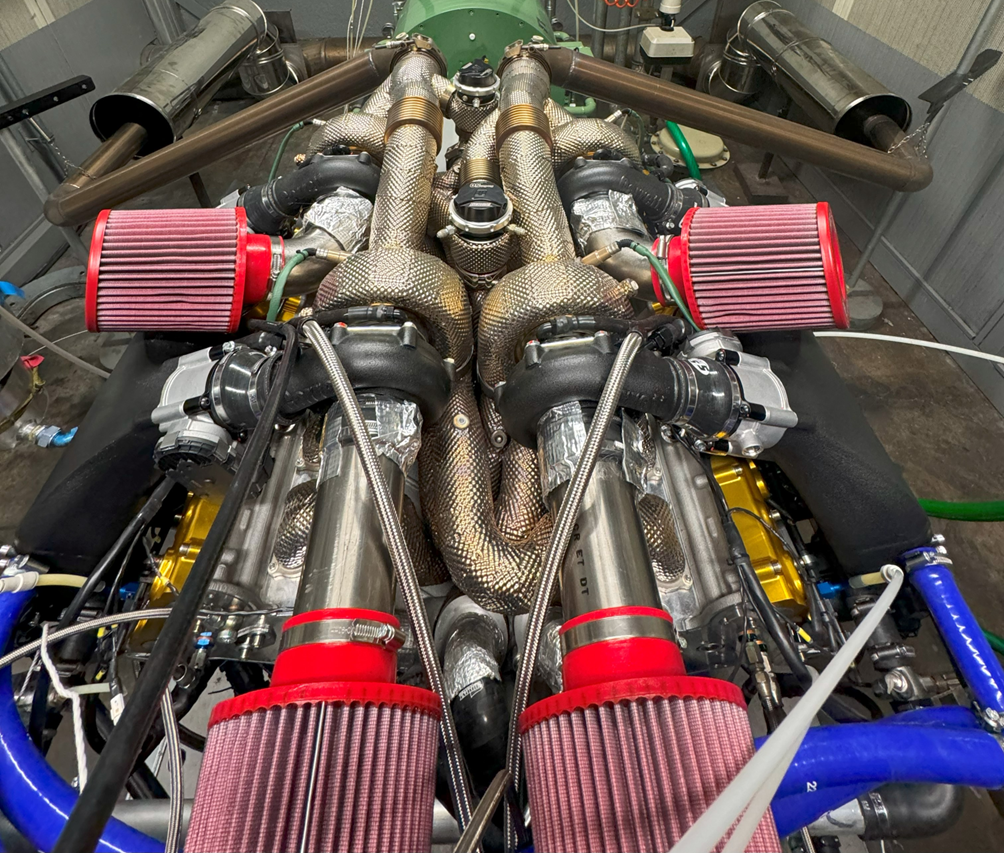

The main requirement for the V12 was pure power: 1,500HP in the initial versions, with the intention of increasing this figure further in the future. This dictated the large displacement and the choice of four turbochargers. The packaging demands of the car determined the engine’s most unusual feature: its V angle, set at 120°. This configuration, combined with a “Hot-V” layout (with the exhausts and turbos inside the V), allowed the compact housing of four appropriately sized turbochargers to deliver the engine’s power, and the design of an efficient exhaust system, maximizing the engine’s volumetric efficiency. The wide V also offers dynamic benefits, significantly lowering the center of gravity. Apart from the turbos, which are the highest part, everything else is very low, almost below the wheels.

The 120° layout required an unusual approach to the crankshaft design. Ideally, the crank pins would have had a 60° offset for an even firing order. However, due to the substantial length of the shaft, it would have been difficult to achieve sufficient rigidity with such spacing. To find the best compromise between strength and firing order, an offset of 50° on the crank pins was chosen. The result is an irregular firing order with alternating spacing of 50° and 70°, instead of the canonical 60°-60. This configuration, while unconventional, allowed for excellent shaft rigidity while maintaining good spacing between firing events. Intensive work was undertaken to optimize the geometry of the crank, including the design of the counterweights and the pin diameter, to increase its stiffness..

In order to ensure correct engine lubrication even under extreme conditions and to maintain a low center of gravity, a dry sump system was adopted. The crankcase is divided into six compartments, each with its own scavenge pump, while the pressure feed is split between two stages. This multi-stage system is crucial for avoiding oil cavitation, as shorter, multiple stages are less prone to cavitation problems at high RPMs compared to a single long stage. The forged pistons are made from aluminum alloy and feature an anti-friction coating on the skirt and an anti-detonation coating with an alumina oxide deposit on the crown, for maximum strength and reliability.

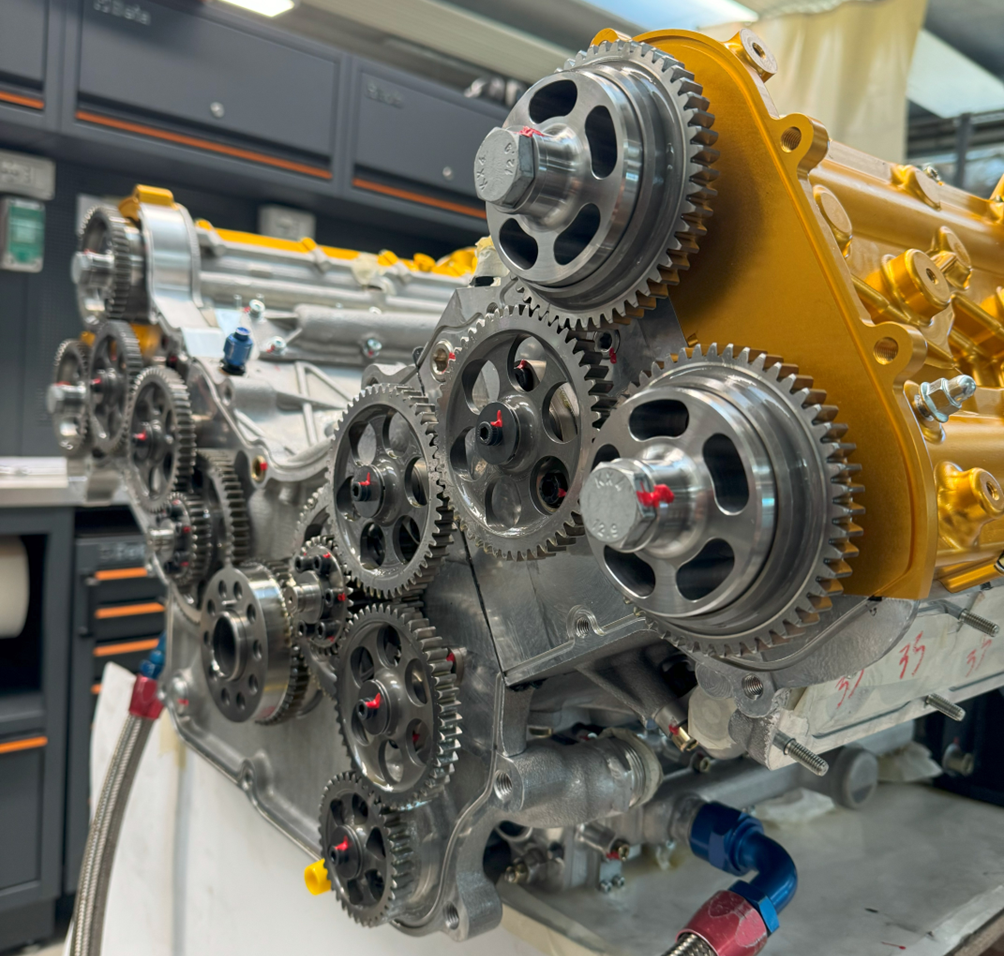

The valvetrain relies on a robust gear drive for the four camshafts. There are no belts or chains running within the engine, except for those powering the alternator and AC compressor. The choice was made to use bucket-type valve lifters rather than the more extreme solution of finger followers. The latter are typically needed only for very high RPMs with aggressive camshaft profiles to maintain proper valve-to-lifter contact. The main focus with these large engines is ensuring the rigidity of the components (block, crankshaft, heads, etc.) and controlling their relative movement: significant effort was made to remove material in less-stressed areas without compromising the engine’s overall stiffness.

Despite the Krafla not featuring a hybrid system and relying solely on the combustion engine, the car is fully compliant with the strict Euro 6 standard, thanks to careful theoretical study and experimental calibration of the combustion chamber. To achieve both high power output and low emissions simultaneously, a precise compromise was needed between the high amount of air entering the cylinder and excellent air-fuel mixing. To comply with Euro 6 regulations, the head must be designed to ensure optimal mixing, which is critical even at low RPM and low air velocity. At high RPM, mixing is naturally good, but at low RPM, if the ducts are too large, air velocity and tumble are low, resulting in poor mixing and a significant increase in emissions.

Further information can be found in the article published in the September 2025 issue of Automotive Powetrain Technology International: https://automotivepowertrain.mydigitalpublication.com/automotive-powertrain-technology-international-september-2025-transmission-tech-international-2025/cover