Born in the Cuneo hills, the Kimera EVO37 is a prodigy of technology developed – just like its progenitor that dominated Group B in the 1983 World Rally season – on the base of the Lancia Beta Monte Carlo.

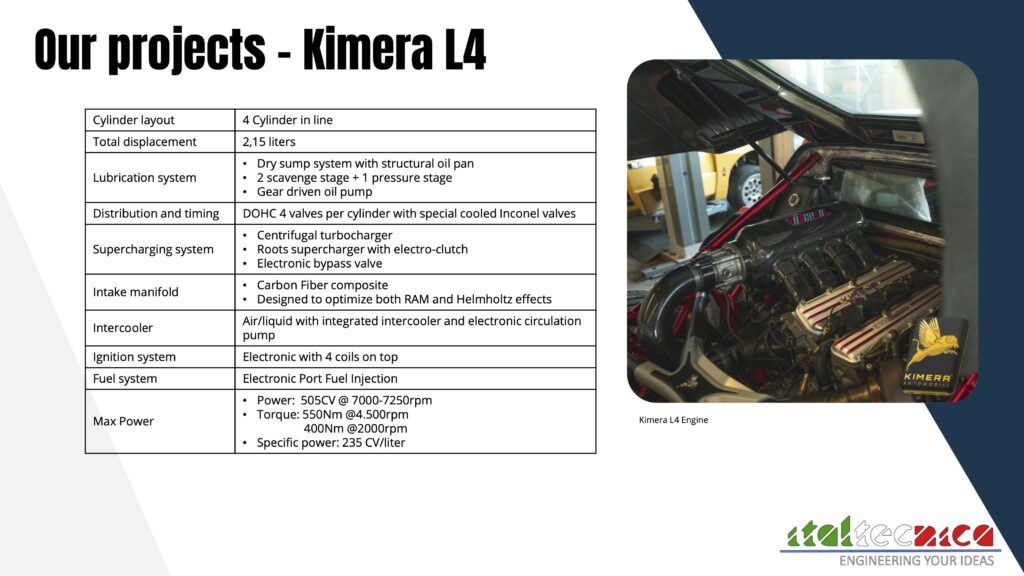

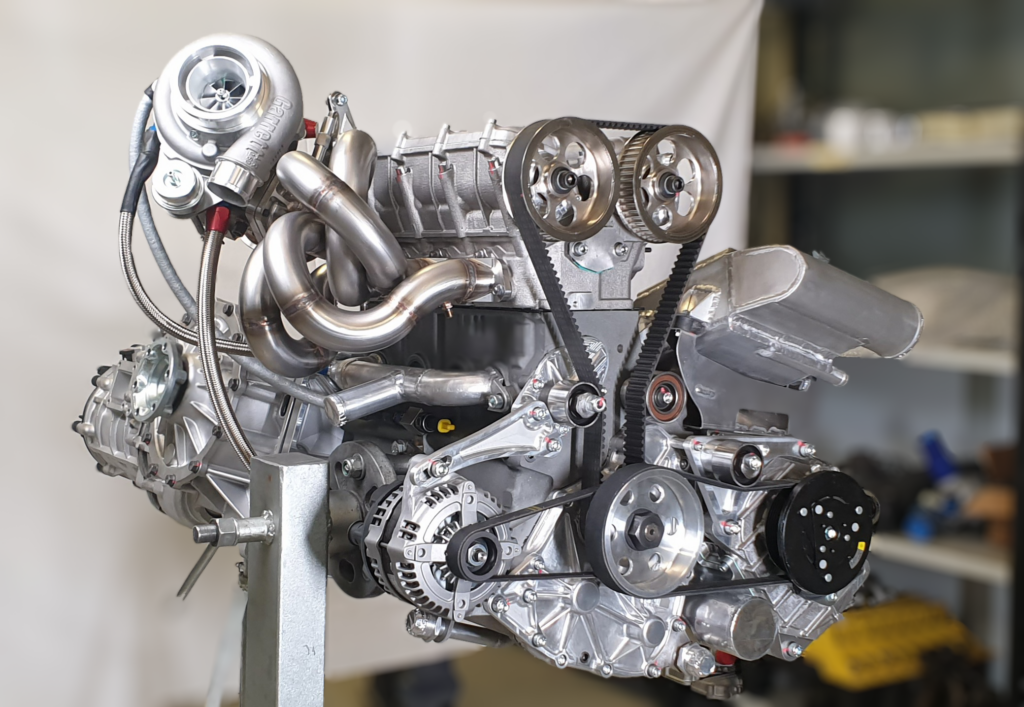

The first creature of Kimera Automobili carries out a powerful 2150cc 4-cylinder in-line engine supercharged by a turbocharger and volumetric compressor combo that provides it with 505 horsepower and 550 Nm of maximum torque at 4500rpm – of which 75% is already available at 2000rpm.

The engine, developed in close cooperation with Engineer Claudio Lombardi – historical designer of the Lancia Delta S4 engine and its “Triflux” evolution – is an entirely “Made-in-Italtecnica” project starting from the design, in all its phases, to complete everything with the consecutive constitution of the in-house assembly line.

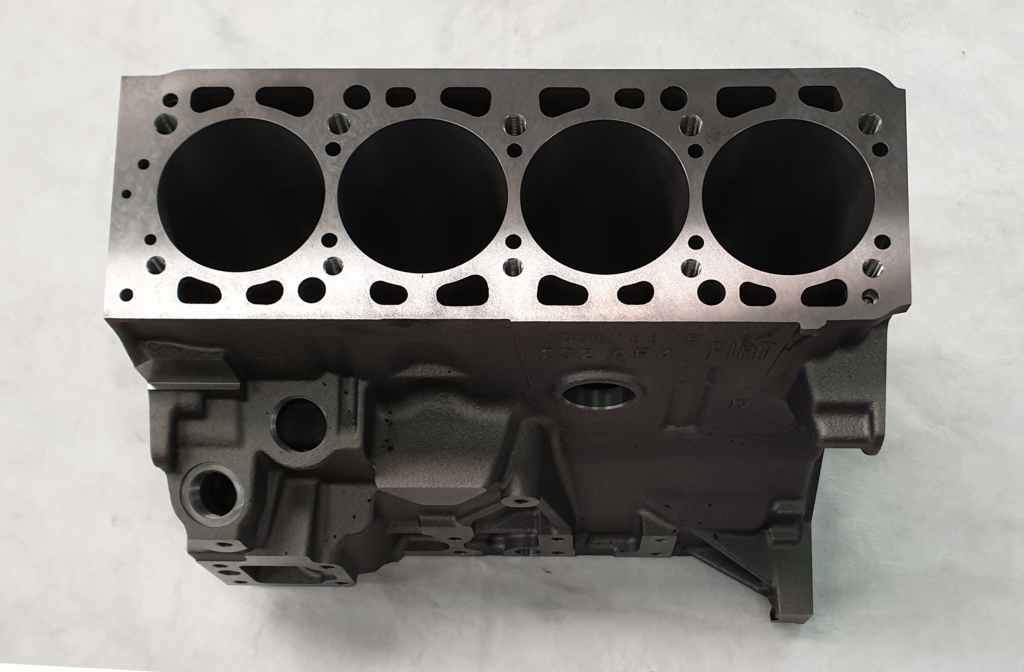

The first peculiarity linked to this powertrain is found in the engine block, populated by a complex system of channels for lubrication and cooling, specifically designed to maximize the aforementioned processes and thus allowing superior performance.

In order to create this articulated channel system – 2 oil jets and 1 cooling channel per cylinder, in addition to the peripheral cooling system – it was necessary to resort to 3D metal printing, printing the block from a molten steel powder directly on the CAD project track, thus allowing us to have an extremely complex product made with absolute precision.

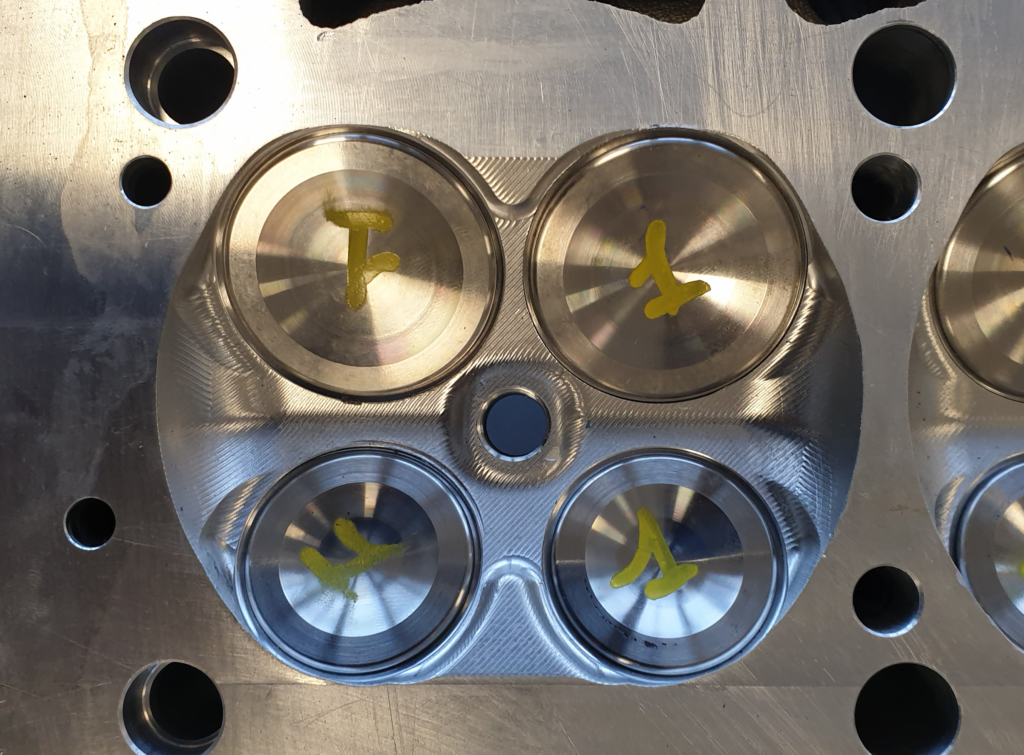

The approach towards total performance has pushed us to evaluate a highly technological solution also with regard to valves, hollows inside the valve stem to ensure superior heat control and dissipation.

They are then placed in their respective valve seats made of beryllium, a material that has a greater thermal conductivity and therefore, working in coupling with titanium valves allows to maximize the heat control and dissipation processes, thus providing a higher overall performance.

In addition to the high level of technology used in the operation of the engine, we have studied in detail the structural resistance of the engine, opting for an extremely cohesive connection between the oil pan and the engine block, with 10 through bolts that firmly anchor the oil pan up to the top of the engine block, thus acting as well as connecting elements as structural components of the engine.

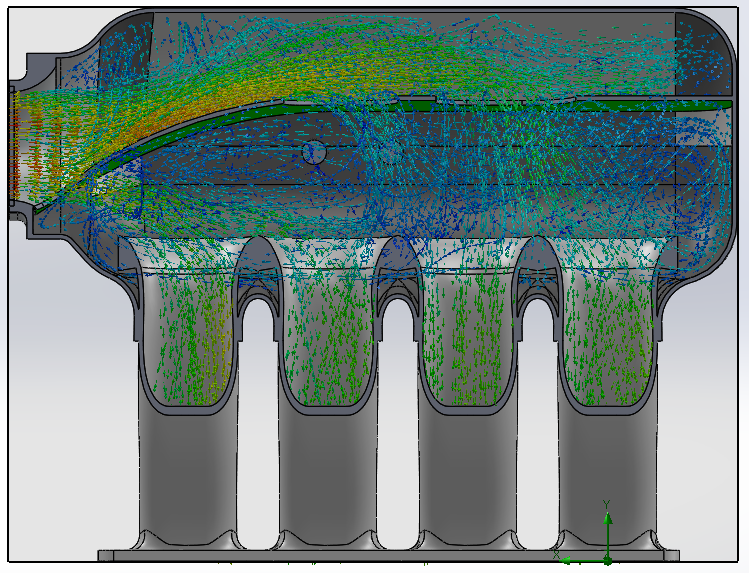

The intake plenum is made with a single-piece carbon fiber body, so as to guarantee maximum structural resistance to stresses and high temperatures present in the engine compartment under operating conditions.

On the inside, the plenum presents a series of aerodynamic elements carefully designed to meticulously control the air flows directed to the cylinders, thus providing an optimized volumetric performance and greater resonance of the intake manifold, recalling the emotions of the 80s sound of the Delta S4.

To meet the customer’s need that required the possibility of being able to see the turbocharger in action through the window, we designed an exhaust manifold with an extremely detailed design, adopting a mix of different techniques to make the final component, from 3D metal printing to CNC milling.

One of the points that most characterize this engine is the superlative specific power, an outstanding 235 horsepower/liter, which make it in fact one of the engines with the highest specific power on the market, speaking of engines used on road-legal cars.

The peculiar supercharging system – turbocharger and supercharger – is the result of Kimera’s choice to remain faithful to the history that marked the legend of the Lancia Delta S4 in the world rally championship: the EVO37, in fact, is structured to be able to bring back to the driver’s mind those same emotions at the first turn of the key, presenting itself with a sound and subsequently with a delivery unmistakably linked to the world of competitions.

Kimera EVO37 Spec Sheet